Electric actuators play a vital role in various applications, from automation systems to medical devices. In today’s technologically driven world, these devices help convert electrical energy into mechanical movement, automating processes and creating efficiencies across industries. This article will guide you through everything you need to know about electronic actuators, their types, applications, and benefits.

What is an Electric Actuator?

An electronic actuator is a device that converts electrical energy into motion. It uses a motor to generate linear or rotary movement, which is then used to control a mechanism or system. These actuators are essential in applications where precision, control, and ease of automation are required.

Types of Electric Actuators

Linear electric actuators are designed to provide movement along a straight path. Commonly used in machinery, these actuators move components or objects in a line, making them ideal for applications requiring precise linear motion. Rotary electronic actuators, on the other hand, provide rotational motion. These actuators are often used in applications where circular motion is required, such as in robotics or assembly lines.

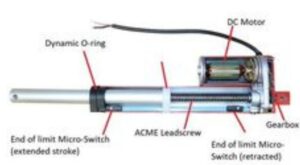

Components of an electronic Actuator

Electric actuators consist of several key components:

- Motor: Drives the movement.

- Gear Train: Transfers and modifies the movement.

- Control Circuit: Regulates the motion.

- Housing: Encloses and protects internal components.

How Electric Actuators Work

Electric actuators operate by using a motor to create motion. The motor converts electrical energy into mechanical energy. This energy drives the actuator’s movement, either in a linear or rotary fashion. The control circuit manages the power supplied to the motor, determining the speed, direction, and extent of the motion. Modern actuators use advanced control circuits to ensure precise and accurate movement.

Applications of Electric Actuators

Electric actuators are used in numerous applications across diverse industries, In manufacturing, electronic actuators automate tasks like material handling, assembly, and packaging. Their reliability and precision make them essential for automated industrial processes. Electronic actuators enable key functions in vehicles, such as adjusting seats, windows, and mirrors, as well as in more advanced safety and performance systems.

Home Automation Systems

For smart homes, electric actuators control various components, such as blinds, doors, and security systems, making homes more comfortable and efficient. In healthcare, electronic actuators help operate beds, diagnostic machines, and other medical devices that require smooth and controlled movement.

Benefits of Electronic Actuators

Electric actuators consume only as much power as required, making them an energy-efficient option compared to other types of actuators. Their design allows for precise motion control, which is crucial for applications requiring high accuracy. Electric actuators typically require less maintenance than pneumatic or hydraulic actuators, which rely on fluids and can be prone to leakage. Despite their advantages, electronic actuators have limitations. They can be more expensive than pneumatic actuators and may not provide as much power in heavy-duty applications. Additionally, they require a stable electrical power supply, limiting their use in remote locations without electricity.

Comparison Between Electric, Pneumatic, and Hydraulic Actuators

Electric actuators generally offer higher efficiency, as they only consume energy when operating. Pneumatic and hydraulic actuators may consume energy even when idle. electronic actuators can be more costly upfront but save on energy and maintenance costs over time, making them cost-effective in the long run. With fewer moving parts and no need for fluid, electronic actuators are easier to maintain than their hydraulic and pneumatic counterparts.

Electronic Actuators in the Age of IoT and Industry 4.0

With IoT and Industry 4.0 advancements, electric actuators have become “smart,” enabling remote monitoring, real-time feedback, and integration with advanced control systems. This development allows industries to automate complex processes with precision and reliability.

Selecting the Right electronic Actuator

Choosing the right electric actuator depends on multiple factors,The actuator must be able to handle the required load without strain. Consider the operating environment, such as temperature, humidity, and exposure to chemicals, which may affect performance. Evaluate the level of control required, including speed, force, and accuracy, to select an actuator that meets these specifications. electronic actuators contribute to sustainable practices by using energy efficiently and reducing the need for hazardous fluids. They also allow for precise control, minimizing waste in automated processes.

Future Trends in Electric Actuators

As technology advances, electric actuator are expected to become more efficient, compact, and intelligent. Innovations in materials, AI integration, and miniaturization will enable them to perform tasks previously reserved for larger, more complex systems. Some common issues with electronic actuators include:

- Overheating: Caused by excessive use or high ambient temperatures.

- Jamming: Often due to misalignment or debris in the actuator’s path.

- Electrical Malfunctions: These can arise from issues with the control circuit or motor.

FAQs about electric actuator

What types of electric actuators are there?

Electronic actuators are primarily divided into linear and rotary types, which offer straight and circular motion, respectively.

Where are electronic actuators commonly used?

They’re used in industrial automation, automotive applications, home automation, and medical devices.

Are electronic actuators energy-efficient?

Yes, electric actuators are highly energy-efficient, only consuming power when in operation.

How do I select the right electronic actuator?

Consider factors like load requirements, environmental conditions, and control needs to find the best fit.

What are the maintenance needs of electronic actuators?

Electric actuators require minimal maintenance compared to hydraulic and pneumatic types, as they don’t rely on fluids and have fewer moving parts.

Conclusion

Electric actuators are essential components in modern automation, providing precision, reliability, and energy efficiency across various applications. As industries continue to evolve, the importance of these devices is expected to grow, powered by advances in technology and sustainability.